Wind and water have a way of finding any weak spot in a vehicle’s glass system. A whisper at highway speed can turn into a howl, and a tiny drip can soak carpets and electronics. I’ve spent years chasing those gremlins in shop bays and parking lots, and I can tell you this: most leaks and wind noise around a windshield start with small oversights in installation, aging seals, or hidden body issues. The good news is that careful diagnosis and a few proven techniques solve the majority of cases without replacing half the car.

This guide walks through how pros think about leaks and wind noise around auto glass, especially the windshield. We’ll cover how to pinpoint the source, the trade-offs between repair and auto glass replacement, where windshield chip repair fits in, and what to do right now if you are getting wet floors or a whistling cabin.

Why wind and water show up at the glass

Glass itself doesn’t leak. The interface points leak. Every window relies on a set of parts that must work together: the glass edge, urethane bond, pinchweld paint, moldings, cowl panel, body seams, and drain paths. Age hardens rubber. Sun bakes adhesives. Dirt clogs drains. Shops sometimes rush urethane cure times. Body repairs leave thin paint on the pinchweld so corrosion creeps in under the urethane. All of that can show up months or years later as wind noise or water intrusion.

There are two failure patterns that come up again and again. The first is a disturbed sealing surface from a previous windshield job. The second is a drainage issue that looks like a glass leak but isn’t. You need to distinguish those early, or you can chase the wrong fix and replace glass that isn’t the culprit.

The anatomy of a quiet, watertight windshield

A bonded windshield depends on three things working perfectly: clean, sound metal on the pinchweld, the right primer system to link the urethane to both the glass and the body, and a consistent adhesive bead that maintains minimum height. If any of those are compromised, you can get an air path at 50 to 70 mph or a water path during heavy rain or car washes.

The modern windshield is structural. It shares crash loads, supports airbags, and stiffens the roof. That is why adhesive choice and cure times matter. A lot of “mystery” wind noise complaints come from urethane beds that are too low. The glass sits a millimeter or two shy of spec, and the reveal molding never quite seals against the body. Air sneaks in, not usually water, and you get a high pitch whistle that changes with crosswinds.

Rubber or plastic moldings at the perimeter are mostly cosmetic, but they do guide air and water. A loose molding can act like a reed in a flute, turning airflow into noise without any actual gap under the glass. That is why you should not judge a leak by the molding’s appearance alone.

First pass diagnostics you can do at home

Before you schedule auto glass repair or replacement, you can gather evidence. It saves time and points the tech in the right direction.

- Simple cabin pressure test: Drive at 45 to 60 mph on a calm day and vary the HVAC. If the noise changes dramatically when you switch from fresh air to recirculation, or when you crack a side window, you’re dealing with a small air path near the top or side of the windshield or a door seal issue, not necessarily the glass bond. Garden hose mapping: With a helper inside and low water pressure outside, work from the bottom up. Keep the stream gentle and focused. Start at the cowl and work along the lower corners, then the sides, then the roofline. Wait a minute at each spot. If water shows inside only when you hit a specific area, note the exact location. Blue tape resets: Apply painter’s tape to bridge the windshield glass edge to the body across one suspect area at a time, then test drive. If the wind noise drops or changes pitch, you’ve narrowed it to a perimeter gap or molding issue at that spot. Do not leave tape on for days in the sun. Talc or chalk dust: Lightly dust the perimeter moldings and the cowl. After a highway run, look for tracks where airflow has cut clean paths through the dust. It helps visualize where the air slips under a loose trim edge.

Those simple checks let you separate a leak from a whistle, and a glass issue from a door or roof rack noise. Half of the vehicles I’ve seen for “windshield noise” actually had a lifted A‑pillar garnish clip or a misaligned wiper cowl.

Where water hides when glass isn’t the problem

Modern vehicles drain water intentionally. The cowl pocket under the wipers collects rain and routes it through grommets and seams down the firewall. Sunroof trays drain to the rocker panels through small hoses. If any of those drains plug or a grommet dries out, water takes the next easiest path, which might be behind the dash or down the A‑pillars, then onto the carpet. That looks like a windshield leak, but it isn’t.

I’ve pulled door sills on SUVs with soaked carpet, only to find a sunroof drain hose disconnected above the kick panel. I’ve also found body seam sealer cracks near the upper corners of the windshield opening on vehicles that had previous paint work. The urethane bond was fine, but water entered through the seam seam itself and followed the glass edge inside. On trucks, the third brake light at the back of the cab is notorious for dripping into the headliner and traveling forward.

If your floor is wet after a car wash but the headliner is dry, suspect lower A‑pillar paths and cowl drains. If the headliner is wet near the visor, suspect upper corners, roof seams, or sunroof drains. That kind of detail will make your auto glass repair visit more efficient.

The professional leak test sequence

Shops use a few structured tests that you can ask for or expect. The sequence matters because you want to move from noninvasive to invasive.

- Controlled water test: A tech uses a leak detector, often a handheld ultrasonic kit. A small emitter goes inside the car. The tech scans outside with a receiver to find air paths around the glass and moldings. It works like a divining rod for sound, and it is surprisingly accurate. Static water test: With trim still on, the shop uses either a water blade or a spray pattern that simulates rain. They avoid blasting the cowl or roof too aggressively at first, because you want to isolate the glass seal, not force water through vents. Trim-off inspection: If a leak is suspected at the bonding edge, the outer moldings and A‑pillar trims come off to get eyes on the urethane bead and glass edge. On some models, that requires new clip kits. A good shop will warn you before this step. Smoke or vacuum: Some use a smoke machine in the cabin and apply low vacuum with fans. The smoke will escape at any air path. Others use talc on the outside and a compressor inside to gently pressurize the cabin, then look for disturbed powder.

Good results rely on patience. Twenty minutes of careful mapping beats hours of guesswork and repeated comebacks.

When repair beats replacement

A lot of leaks and wind noises resolve without a new windshield. If the glass is well bonded but air sneaks under a molding edge, the fix may be as simple as replacing the molding and its clips, or adding a narrow bead of nonhardening sealant under a decorative trim. I’ve tamed howls by shimming a cowl panel to restore its designed airflow path, essentially lifting the leading edge a millimeter so air doesn’t buffet beneath it.

If the urethane bead shows a small void at the perimeter, some manufacturers allow “decking” or top sealing with a compatible non-structural sealant, but that is a judgment call. You never rely on an external bead for structural integrity. It can stop water and silence air at the edge if the underlying bond is sound. I only consider that when diagnostics prove the bond is intact and we are addressing a surface path.

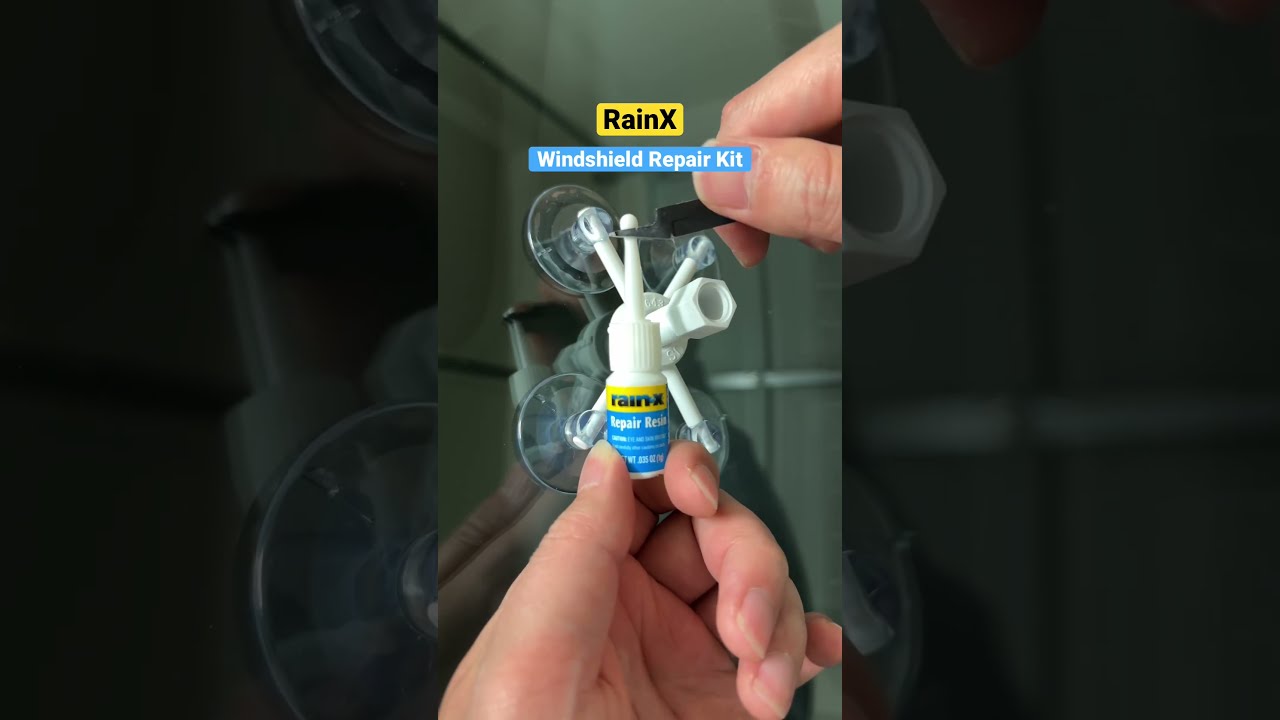

If wind noise arrives after a windshield chip repair, the repair itself is rarely the cause. Rock chips that penetrate the outer layer can create tiny surface irregularities. At highway speeds they sometimes sing, especially on frameless performance cars with steeply raked glass. A quick polish usually quiets them. From a structural perspective, windshield chip repair is still the right move to stop cracks from spreading and to preserve the factory seal.

When auto glass replacement is the right call

There are clear cases where you should replace the windshield rather than patch around it. Any sign that the urethane did not bond to the glass or the body is a showstopper. You might see lift with gentle suction, corrosion under the bond, or a bead that never achieved the correct stand-off height. If the pinchweld paint is compromised, the glass must come out so the metal can be cleaned, primed, and repainted before a fresh install.

Body shops sometimes use aggressive solvents or grinding near the opening during unrelated repairs. If the paint film is thin where the urethane needs to grab, the bond will eventually fail. The safest course is to remove the glass, restore the pinchweld per the adhesive manufacturer’s instructions, and reinstall with the right primers. That also applies to vehicles where aftermarket glass was installed with the wrong primer system. You cannot fix primer compatibility with an external seal.

Cracks that reach the edge of the windshield are another red line. They can compromise the bond and reduce structural performance. Here auto glass replacement is not just a leak fix, it is a safety fix.

Choosing glass, urethane, and technique

Replacement quality matters as much as the decision to replace. Two windshield installs can look identical and behave very differently at 70 mph.

I look for OE or OE-equivalent glass for complex shapes or vehicles with advanced driver assistance systems. The optical quality varies. Some aftermarket glass is excellent, some adds distortion that can look like heat waves near the edges. Distortion itself doesn’t cause leaks, but glass that does not match the body aperture can load the urethane bead unevenly and create paths for air. On sensitive models, the safer route is OE glass.

The urethane should meet the vehicle maker’s requirements for strength and safe drive-away time. Fast-cure urethanes can reach handling strength in as little as 30 minutes, but that number assumes proper temperature, humidity, and bead geometry. If you leave with a noise or a leak right after a replacement, ask about cure conditions and walk through how the bead was set. The adhesive bead height and width are not arbitrary. Installers use setting blocks and stops to suspend the glass at the correct stand-off. If the bead is too thin at one corner, you will hear it.

Molding and clip kits are not optional when they are one-time-use designs. Reusing deformed clips is a recipe for flutter and whistles. I’ve fixed more than one “bad glass” complaint by replacing a handful of $2 clips that were bent flat during the prior install.

ADAS, recalibration, and noise

Newer vehicles use the windshield to house cameras and sensors. After auto glass replacement, those systems need calibration. If they are not seated correctly or the glass curvature is off, the camera can sit a hair out of plane, which often shows up as lane-keeping errors or glare, not leaks. But I mention it here because the mounting brackets and rain sensors require proper gels and seals. A mis-seated rain sensor can cause the wipers to behave erratically and make noise right where drivers think the wind is coming in. Be sure the shop handles both the calibration and the sensor reseal.

Preventive care after a replacement or repair

The first 48 hours after a replacement are critical. Avoid slamming doors. Don’t power wash the perimeter. If your installer gave you a cure window, respect it. On a hot, dry day the adhesive skins faster on the outside than inside. It can look set while still soft inside the bead. High cabin pressure spikes from door slams can push microscopically on the wet urethane and open a path that only shows up later as wind noise.

Keep drains clear. If you park under trees, the cowl can clog in a week. Pop the hood, remove leaves around the wiper arms, and flush with low pressure water. Check sunroof drains twice a year by pouring a small cup of water into each corner and watching for a steady trickle under the car. If it backs up, address that now, not after water stains the headliner.

Moldings and trims are wear items. UV cooks them. If you see shrinkage at the corners or loose edges that you can lift with a fingernail, replace them before they turn into whistles. It is far cheaper than chasing noise on the highway.

Special cases that fool even experienced techs

Some vehicles are just tricky. Frameless door glass on coupes and convertibles is sensitive to alignment. Owners blame windshields for cabin noise that actually comes from the roof or door glass not sealing to the weatherstrip after a battery disconnect resets the indexing. The fix is an initialization procedure, not a new windshield.

Pickup trucks with aftermarket light bars or cab visors generate harmonics. Remove the bar and the whistle vanishes, reinstall it with rubber windshield replacement Avery County isolators and low-profile mounts, and you silence the resonance. Similarly, mirror caps and A‑pillar mounted accessories can create noise that feels like it originates at the windshield. Tape over the seams on a test drive. If the pitch changes, that is your clue.

On older vehicles with butyl-set glass, you might inherit a system that predates modern urethanes. Butyl is not structural and cold flows over time. If you plan to keep the car, moving to a proper urethane installation upgrades safety and usually eliminates chronic water paths. The prep is more involved, since butyl residue must be fully removed and the pinchweld conditioned, but the result is a cleaner, quiet cabin.

What to tell the shop to get the right result

A clear story shortens the diagnostic loop. Share when the noise or leak happens, what speed and weather conditions, and whether the windshield has been replaced before. If you noted changes during your tape or hose tests, mention the exact locations. If you had windshield chip repair recently, tell them when and where on the glass. A small repaired pit near the A‑pillar probably isn’t the source, but that information helps the tech rule it out.

Ask how they plan to test. A shop that mentions ultrasonic testing, trim-off inspection, and pinchweld prep will likely take the time to fix it correctly. If they jump straight to slathering sealer around the perimeter, be cautious. External sealing can be a valid step, but not as a blind first move.

Costs, time, and realistic expectations

Leak diagnostics range widely. A straightforward water test and molding reseat might take an hour. Trim removal and bead inspection might take two to three. If the windshield must come out, plan for half a day plus cure time, sometimes more if corrosion repair is needed. Sunroof drain fixes or cowl sealing often sit outside the auto glass lane and may involve a trim specialist.

Expect parts costs for moldings and clip kits in the tens to low hundreds, depending on the vehicle. Auto glass replacement varies from a few hundred for common models to well over a thousand for vehicles with heated glass, acoustic interlayers, HUD, or camera mounts. Insurance may cover windshield replacement, particularly if you carry glass coverage, but they usually will not pay for wind noise correction unless tied to a covered loss.

A final water test and drive should be part of the handoff. Stand with the tech. Replicate your conditions. Listen together. Good shops welcome that, because it closes the loop.

The role of acoustic windshields and aftermarket differences

Many newer cars use acoustic laminated windshields. They include a sound-dampening interlayer that cuts high frequency wind noise. If you replace that with a non-acoustic part, you will likely hear more wind even if the seal is perfect. Owners sometimes think something went wrong with the installation when the difference is material spec. If your vehicle came with acoustic glass, match it. The part number and a small icon on the glass usually confirm it.

Some aftermarket glass has slightly different edge tapers or frit band widths. That can change how moldings bite. If the molding relies on a very specific edge thickness, a mismatch can loosen the clip hold. The fix is not to force the wrong molding to fit, it is to source the correct glass-molding pairing or use the OE clip kit that compensates for the difference.

A step-by-step plan if your car is leaking or howling today

- Protect the interior first. Pull floor mats, blot standing water, and run a fan. Electronics under the carpet can get expensive quickly. Map the symptom. Use the hose and blue tape tricks to narrow the area. Note speed, wind direction, and weather. Inspect drains and easy trim. Clear leaves at the cowl, verify sunroof drains, and press along moldings to feel for loose sections. Decide on repair vs replacement. If you see corrosion, obvious gaps, or a history of poor install, plan for auto glass replacement. For noises tied to moldings or cowls, start with repair. Choose a shop that tests, not guesses. Ask about their adhesive system, moldings policy, and whether they perform ultrasonic or smoke testing and ADAS calibration if needed.

Final thoughts from the bay floor

Most wind noise and water leaks around a windshield yield to methodical work. I’ve had vehicles come back three times from other shops with new glass each time, only to find a loose corner molding and a clogged cowl drain were the real villains. I’ve also met owners who lived with a whistle for a year because “that’s just how these cars are,” then watched their faces when a fresh set of A‑pillar clips and the right bead height restored silence.

If you treat the windshield as part of a system and resist the urge to smear sealant over everything, you’ll solve the problem faster and more permanently. Use windshield chip repair to preserve the integrity of the glass and prevent cracks. Choose auto glass repair where trims and drains are at fault, and opt for auto glass replacement when the bond or the glass itself is compromised. Your ears, your carpets, and your airbags will thank you.